Stacking packages on a pallet is harder than it seems — you have to think about the shape of the different boxes and how much they weigh, for example, to make sure the boxes fit next to and on top of each other and that the pallet doesn’t tip over to one side. With software first designed for NASA robots in space, robots can actually analyze all these factors to determine the best way to grasp, lift, move and set down the items, as well as the fastest way to unload, all while compensating for weight, orientation, and even crushed or wet containers.

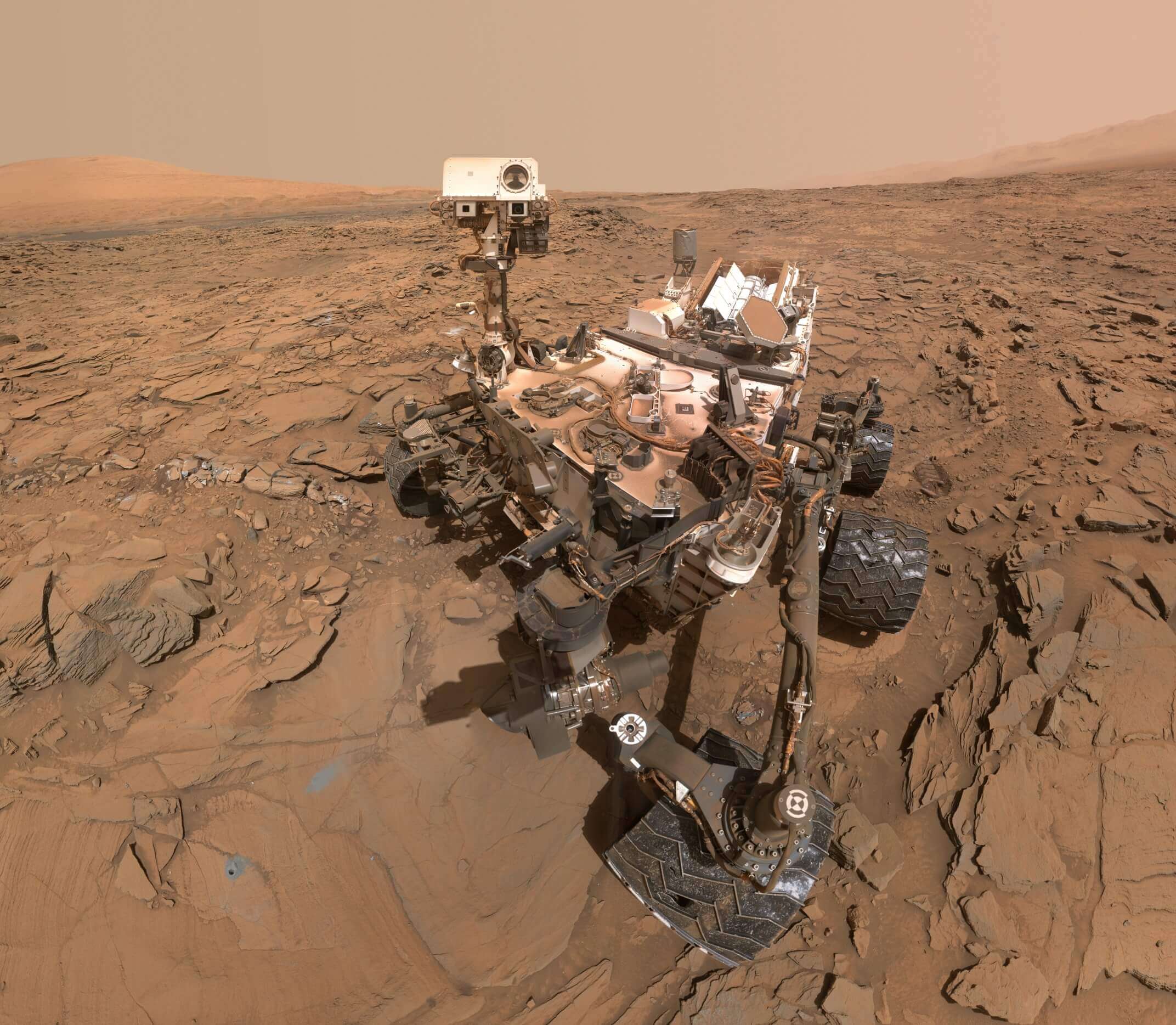

NASA uses robots where humans can’t go — like on Mars — or for tasks when humans are too busy, including on space station. The robots look different, depending on what they need to do, and they need special software to power the robot’s “brain.” Some of that software aims to give the robot specific instructions for any kind of situation it might find itself in (like how to move to avoid tripping over a rock) but newer artificial intelligence software aims to give the robot some parameters and the ability to determine how to respond to new situations itself.

Learn more about how NASA helped develop technology that impacts system health monitors within your city's manufacturing environment!