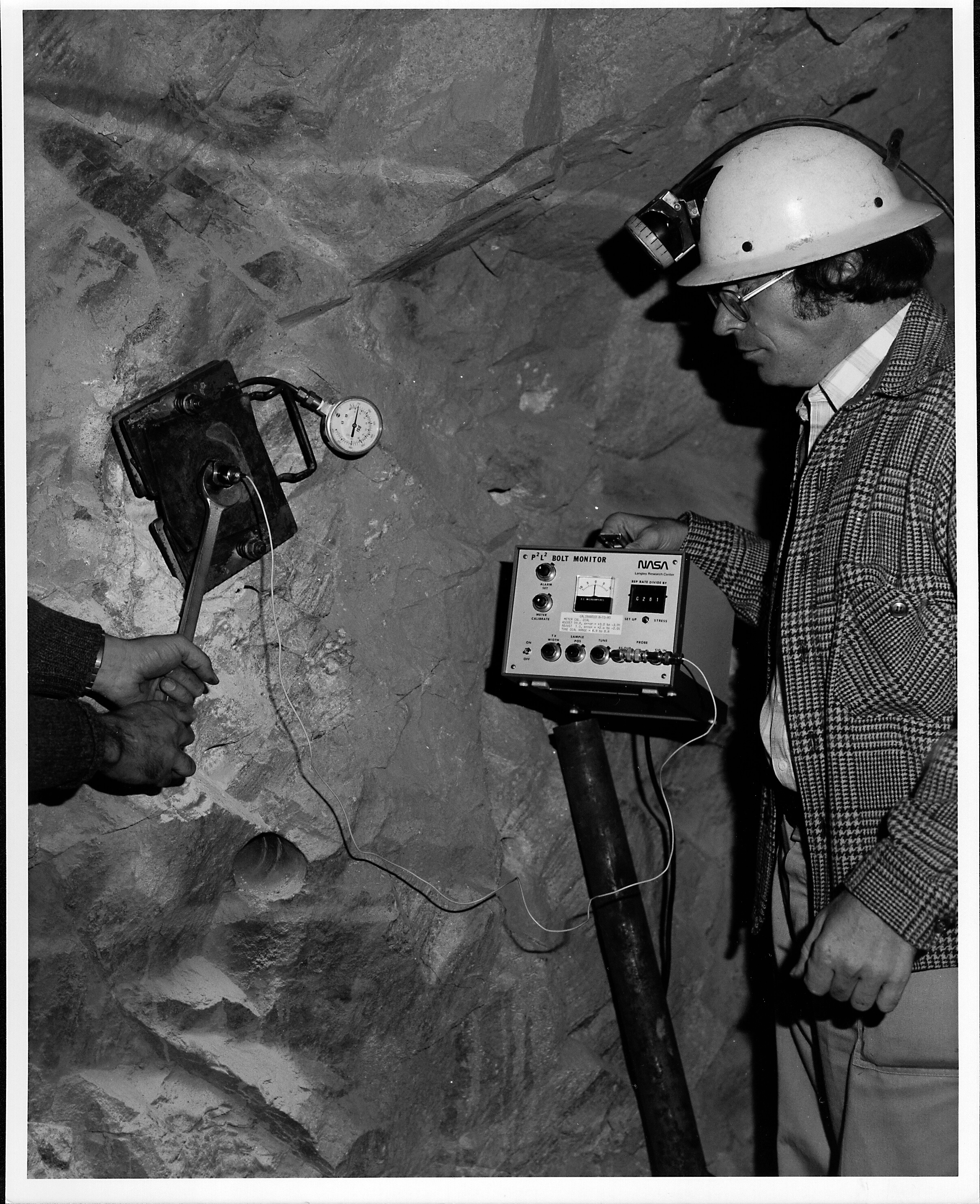

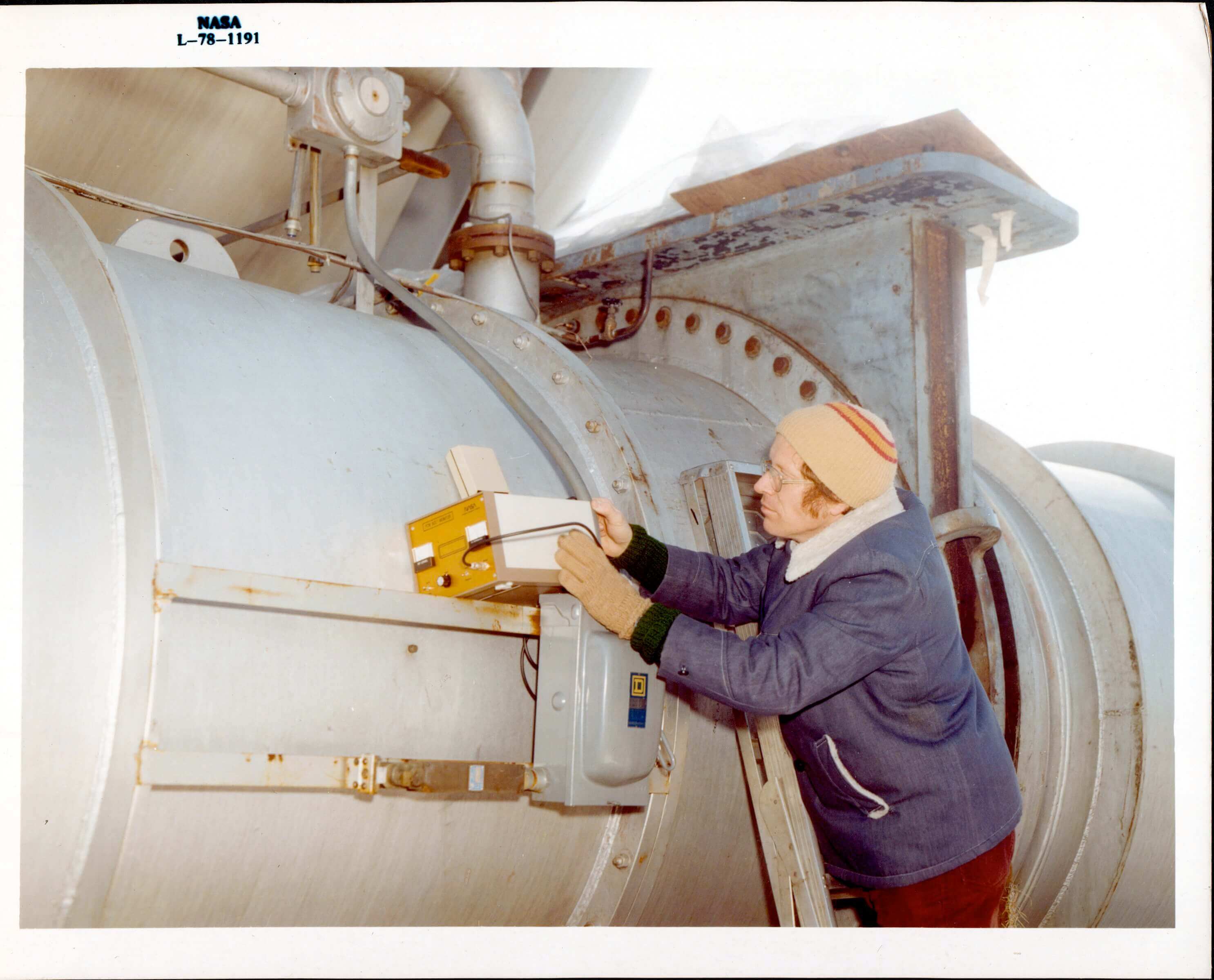

When the U.S. Geological Survey asked NASA for help determining the load on huge mine roof bolts, a NASA engineer successfully modified an ultrasonic device he had developed for measuring bolt elongation. The technology makes each bolt its own load monitor, increasing mine safety. Further evolution of the technology has led to non-destructive railroad track evaluation, groundwater analysis, materials testing, radiation dosage monitoring for cancer patients, and medical testing.

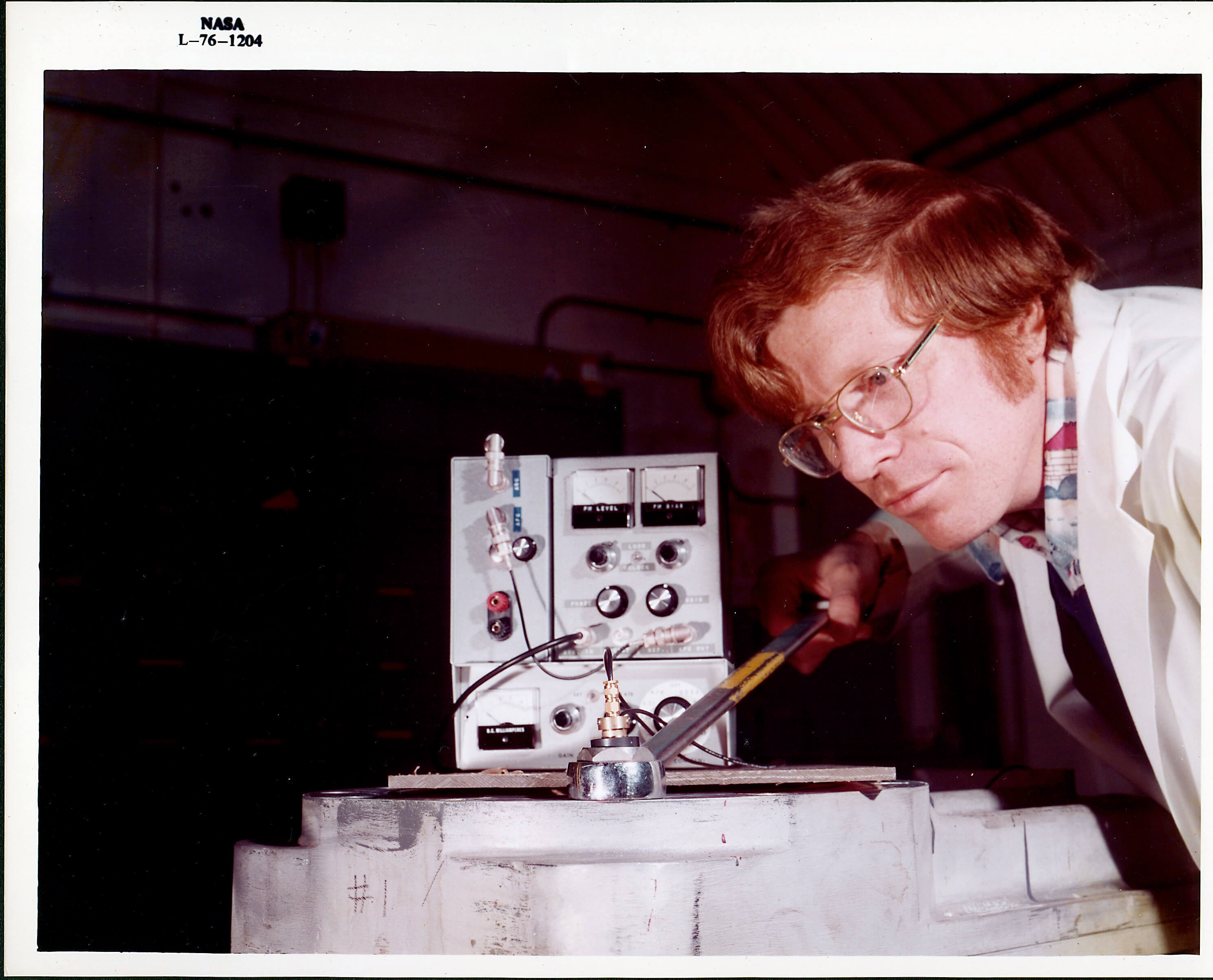

After an investigation concluded that a NASA wind tunnel accident had resulted from improperly tightened bolts, one of the agency's engineers developed an ultrasonic device that could measure bolt elongation. Seeing a potential for more applications, he continued to develop the technology, modified it for mine safety, and eventually came up with an acoustic strain monitor that would go on to be modified for applications across a wide range of fields and industries.

Learn more about how NASA helped develop technology that impacts improved mine safety within your city's manufacturing environment!