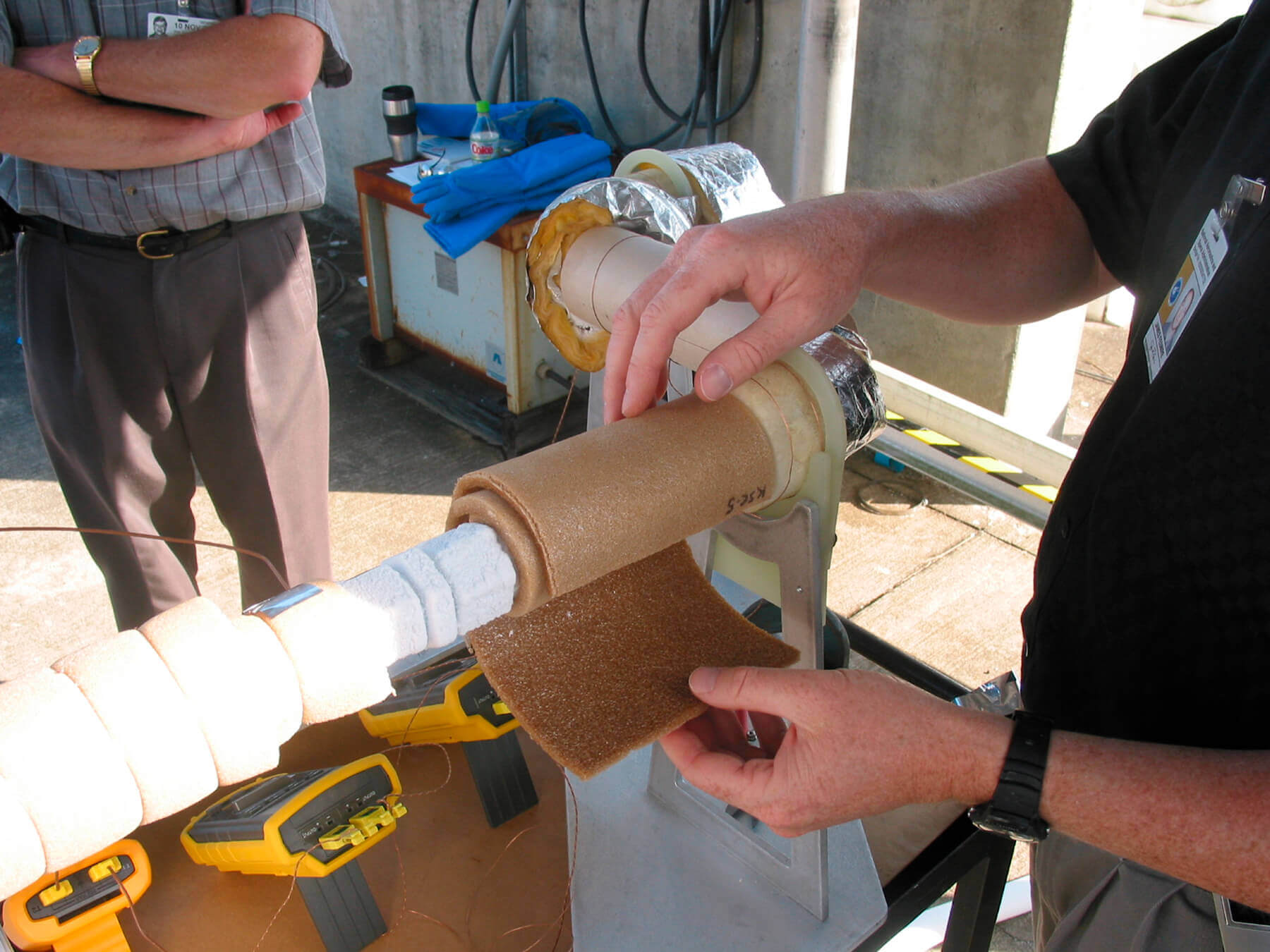

NASA created a polyimide foam that proved to be an effective insulator across a surprising range of temperatures. Two companies licensed and modified the material, with one adapting it to pipe insulation aboard ships and the other marketing it in sheets to be cut and applied by the consumer. The insulation is lightweight, flexible, nonflammable, nontoxic and environmentally friendly.

NASA engineers were trying to come up with a new composite for building supersonic aircraft, but whenever they solidified it, it turned to foam. They noticed, though, that the foam had some remarkable insulating properties. The agency licensed the material to one company that helped make the foam for potential space applications and to another that worked with NASA to make it lighter in weight and cheaper to produce.

Learn more about how NASA helped develop technology that impacts insulating foam within your city's manufacturing environment!